Injection Moulding Vinyl Release Air

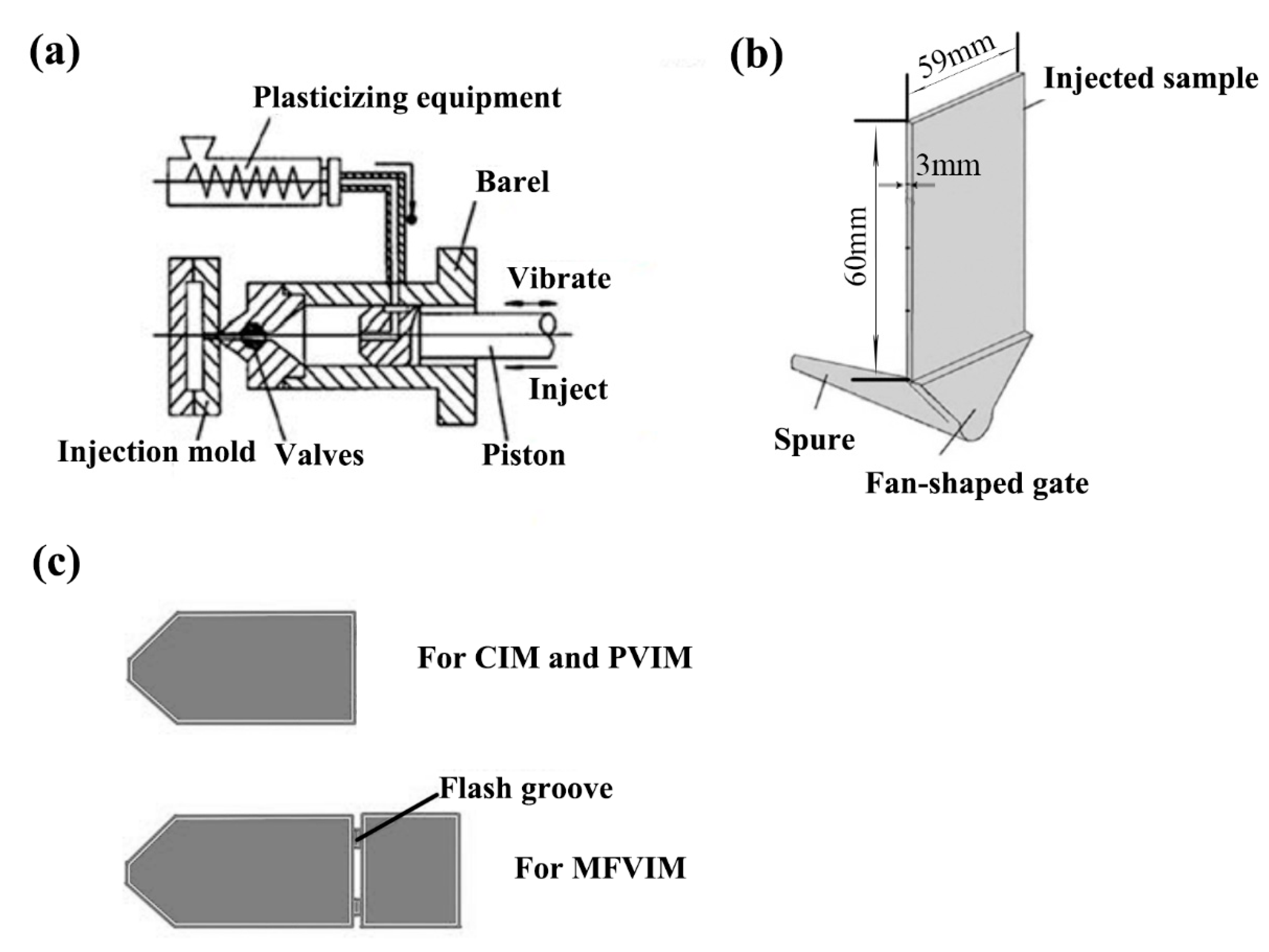

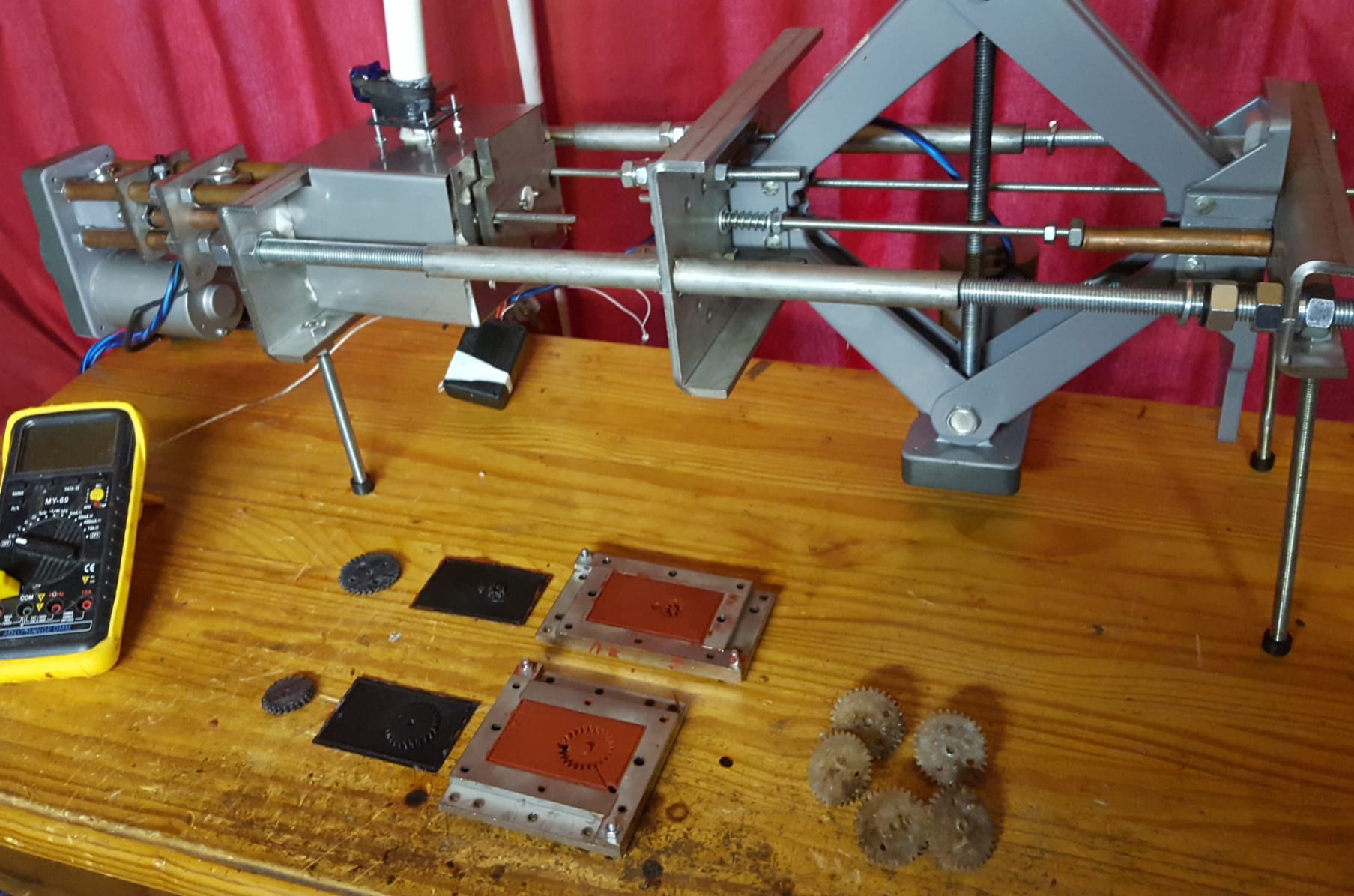

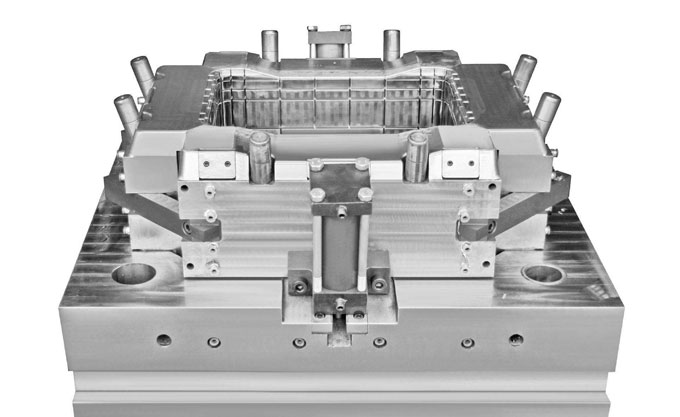

Successful processing of flexible vinyl compounds by injection molding is dependent upon a wide range of variables such as mold design screw geometry machine size and shot size.

Injection moulding vinyl release air. Molders choice is an injection molding supplier for the plastics processing industry. 225 f 107 c 446 f 230 c 475 f 246 c 600 f 316 c painting air dry. The advantages of plastic injection molding for manufacturing parts methods include fast production speed high efficiency automation of operation shapes and size flexibility. Note that this is opposite to polyethylene in which a decrease in crystallinity correlates to a decrease in density.

Painting with bake up to 350 will withstand. Polyurethane pur and pu is a polymer composed of organic units joined by carbamate urethane links. However the density increases due to the higher molecular weight of acetate over ethylene. Increasing vinyl acetate content decreases crystallinity and influences all properties related to crystallinity.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or mold injection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. For optimum processing exact machine conditions will need to be determined by the processor. The following information will aid the processor in attaining the best. Sticky parts were the status quo during the infancy of the molding industry and even as technology has evolved and mold design and mold making materials have improved mold release agents still play a significant roll in improving cycle times and helping.

This is because melted pvc can give off a corrosive toxic gas. 160 161 mold rust preventives. The mold release agent comprises a functional siloxane a crosslinker a thickening agent a base and water. Mold release agents.

Moreover the injection molding products are accurate in size easy to be replaced and the mold parts can be formed into complex shapes. 31 a semi permanent water based mold release agent is used for composite materials e g graphite containing fuselage or wings parts. 190 air blowers ionizing. Air hose coiled.

In handbook of antiblocking release and slip additives third edition 2014. While most polyurethanes are thermosetting polymers that do not melt when heated thermoplastic polyurethanes are also available. Polyurethane polymers are traditionally and most commonly formed by reacting a di or triisocyanate with a polyol since polyurethanes contain two types of. The functional siloxane is dispersed in water.

Polyvinyl chloride can be injection molded just like other plastics but the inclusion of chlorine in the material complicates the process.