How Is Zip System Wall Panel Made

This high performance formulation combines the durability of silicones with the toughness of urethanes.

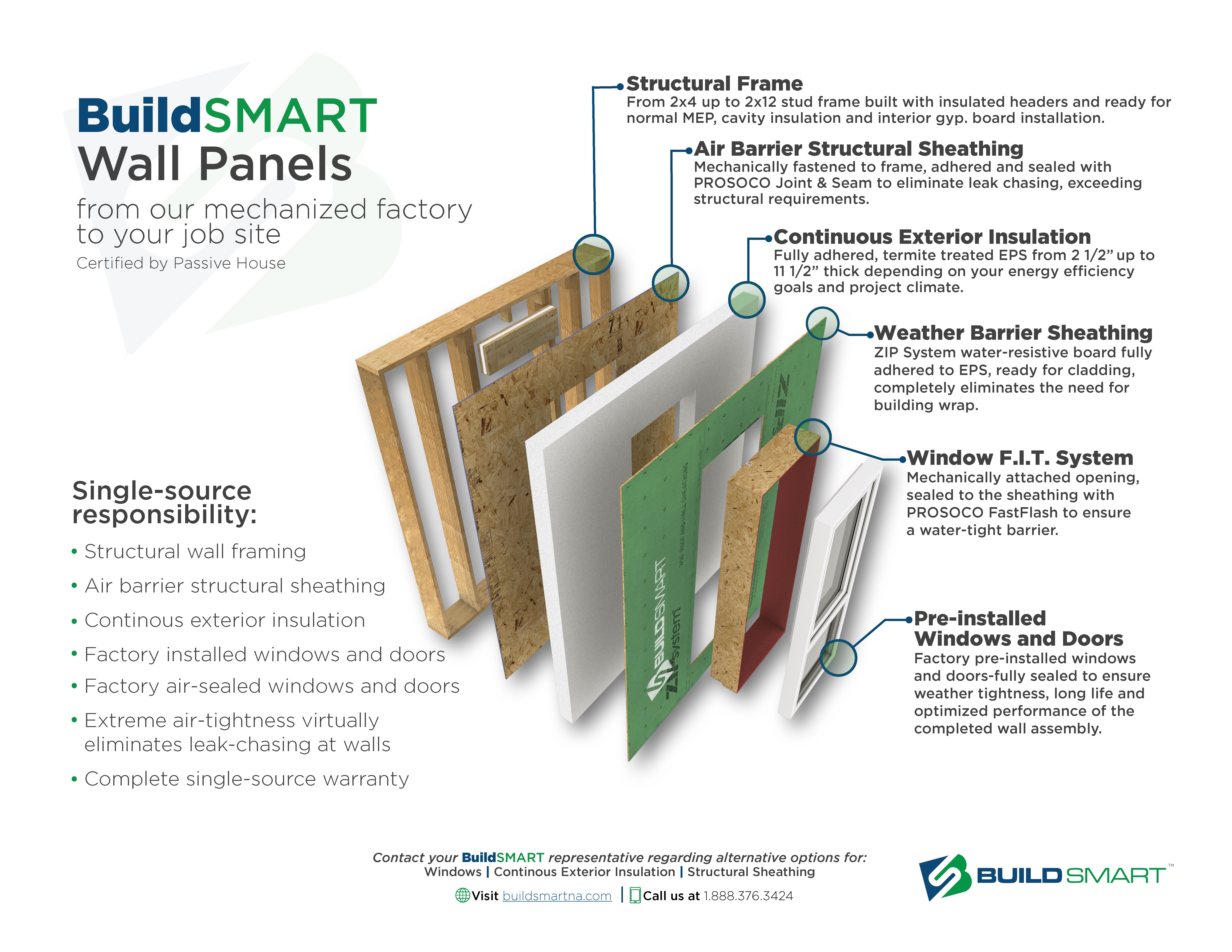

How is zip system wall panel made. Position it with that in mind when zipping your panels together. Zip system roof and wall sheathing panels are oriented strand board osb structural panels with built in protective overlays that eliminate the need for building wrap or roofing felt. When used as part of a zip system building enclosures system they are covered under a 180 day exposure guarantee and 30 year limited warranty 1. Three panel thicknesses with various dimensional options let you choose the right panel for each design and application.

With integrated structural water and air management layers zip system products offer interchangeable options for optimal roof and wall performance. Start at the top look for top left and zip the panels downwards. Zip system 5 8 cat ps2 10 tongue and groove osb sheathing application as 4 x 8. Throughout history home construction has been shaped by two forces.

The zip system sheathing panels and the zip system tape. One that offered durable structural performance combined with moisture and air protection in an easy to install sheathing system. Sheathing tape by advantech. This panel comes with velcro strips.

Zip system is manufactured by huber engineered woods llc. All sizes are engineered to provide optimal roof and wall performance. Zip system zip 1 2 cat ps2 10 tongue and groove utility osb application as 4 x 8. Zip system sheathing and tape is an innovative structural roof and wall system with an integrated water resistant and air barrier that streamlines the weatherization process and transforms it with a simple two step installation.

The zip system includes two main components. Zip system r sheathing is the simple all in one structural panel with built in exterior insulation. Made with advanced acrylic adhesion specially formulated for application over a wide temperature range zip system tapes are pressure activated to create a powerful bond that gets stronger over time. Use the 2 5 foot panel as a doorway.

For pricing and availability. Just put up the panels and tape the seams. Install the panels tape the seams with hubers zip system tape and the building is rough dried in. Featuring integrated moisture air and thermal protection zip system r sheathing completely reimagines traditional wall assemblies by streamlining exterior water air and thermal management.

The panels are made up of osb wood structural sheathing with an exterior facer of medium density phenolic impregnated polymer modified material. This will enable you to unzip from the bottom once the barrier is installed similar to the fly of a tent.