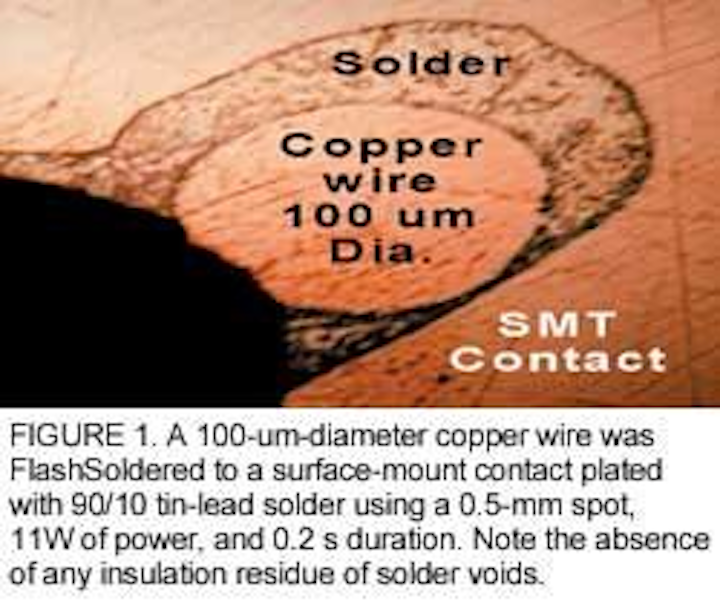

Hot Bar Reflow Soldering Process

In preparation for the hot bar reflow soldering process the following preparation steps need to be taken.

Hot bar reflow soldering process. The flex is positioned in the parts fixture ensuring alignment of both sets of pads. Reflow soldering process overview. 3 layouts for hot bar reflow soldering. A process start signal is given to the soldering control unit.

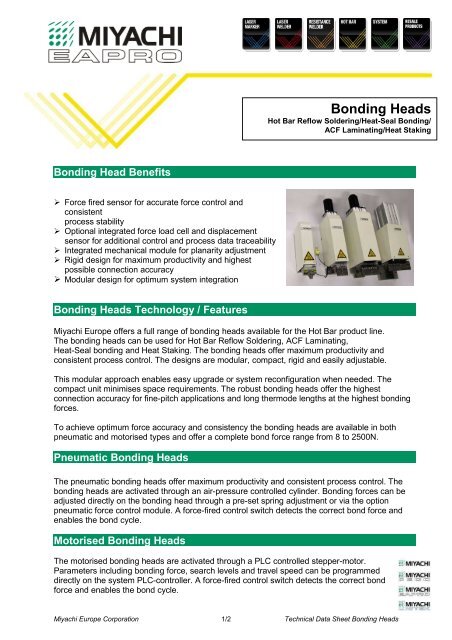

Pressure is applied during the entire cycle including heating reflow and cooling. The base substrate is located in a fixture and flux is applied to the pads. For components that require a very precise positioning hot bar reflow soldering is the most ideal process. Pulsed heated soldering differs from traditional soldering because the reflow of solder is accomplished using a heating element called a thermode which is heated and cooled down for each connection.